By Jim Rosenthal

Since the first Corsi-Rosenthal Box Air Cleaner was made in August of 2020, we have received many questions about the necessity of using new, fully-assembled filters in each filter change. So we have developed an alternative using permanent metal frames. Instead of changing all of the filters by reassembling the CR box with new filters, you just change the media. The frame is “permanent.” This should lower cost and waste.

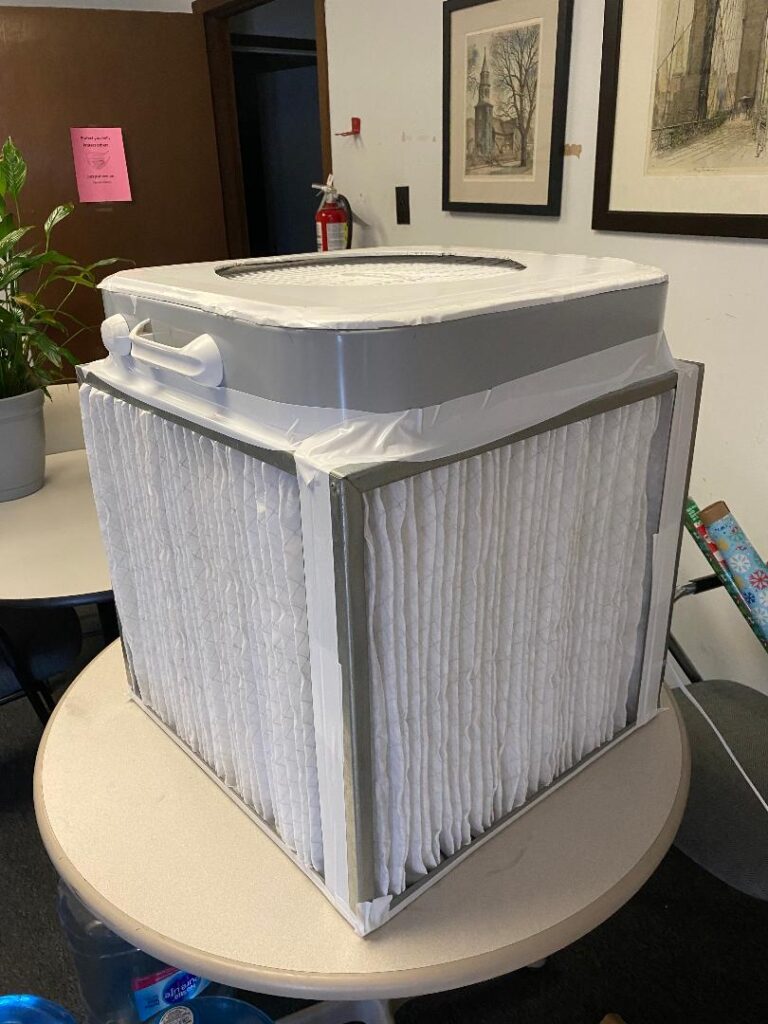

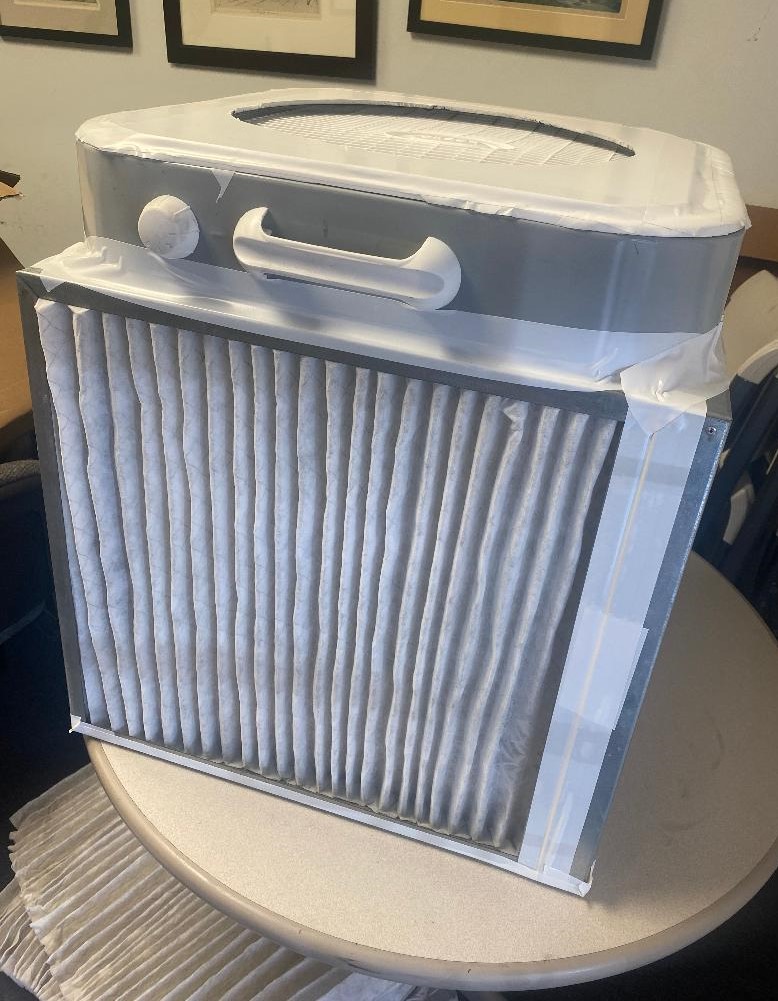

The Permanent Frame Corsi-Rosenthal Box is constructed the same way as the conventional version. The holding frames (like those shown in the picture below) are the 4 sides of the box. Each holding frame has a metal grid to hold the filter media in place. This grid needs to be on the inside so that the force of the airflow pushes the media to the frame. Cardboard can be used on the bottom. The fan is on top – pointed up.

Permanent Frame – Corsi-Rosenthal Box using MERV 13 – 2″ Pleated Media

An advantage of this design is that one can easily alter the media (or medias) used in the final CR Box air cleaner. For example, our normal MERV 13 – 2″ pleated filter has 15 pleats per foot. So a 20X20X2 MERV 13 filter would have 25 pleats. For this test, I decided to use 30 pleats. The 5 extra pleats added 400 square inches of media per filter or 1,600 square inches for the CR Box. The more filter media – the lower the media velocity. Lower media velocity lowers resistance and should increase filter efficiency.

The major factor to consider in using pleated media “packs” in a holding frame is that there is no glue to ensure a good seal. What is the effect on filter efficiency? As it turns out – very little. Two reasons. One, the holding frames are designed with a “lip” so that air does not go through the edge of the filter. Two, the filter media is 1/2″ wider than the holding frame. This extra media is forced to the sides of the frame so that there is very little “Bypass.”

Here are the particle measurements of the Permanent Frame CR Box using 30 pleats per filter:

| Particle Size | Ambient | CR Box – MERV 13 – 2″ Media | % Reduction |

| 0.3 um | 402,700 | 155,000 | 62% |

| 0.5 um | 66,400 | 15,400 | 77% |

| 1 um | 14,000 | 1,400 | 90% |

| 2.5 um | 6,700 | 300 | 96% |

| 5 um | 1,000 | 200 | 80% |

| 10 um | 400 | 100 | 75% |

These results are in line (maybe better) than the four filter Corsi-Rosenthal Box with standard MERV 13 filters. Certainly, there does not appear to be any drop-off in performance.

As we can see on the noise measurements, it might be lower than the standard CR Box versions using the Lasko fan. This may help in some settings like classrooms where noise is a huge factor.

| Fan Speed | Noise in Decibels |

| 1 | 47/48 Dba |

| 2 | 54/55 Dba |

| 3 | 59/60 Dba |

Permanent Frame – Corsi-Rosenthal Box using MERV 11 – High Loft Polyester Media

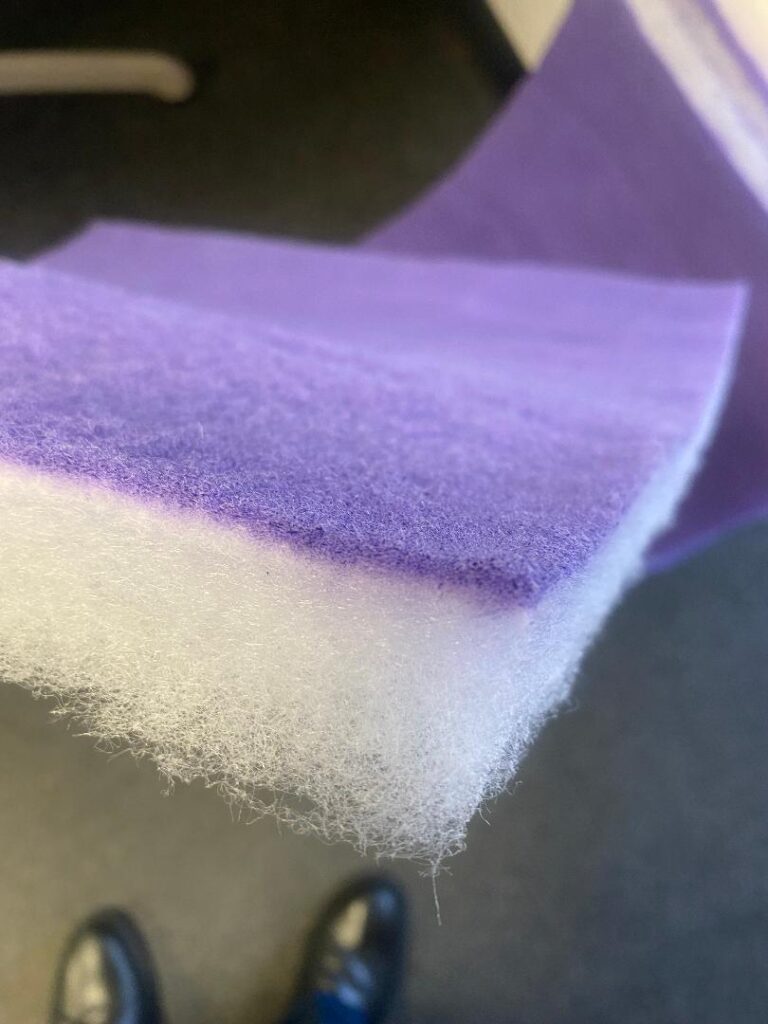

Holding frames are used primarily in conjunction with what are called “high loft media” filter pads. These are easy to change and very effective on large particles. They work primarily on two filter “mechanisms” – impaction (impingement) and staining. Impaction happens when larger particles hit and attach to fibers in the filter. Straining happens when the particles are too large to pass through the gaps between fibers. Since these filters are not pleated, they have the same face velocity as media velocity. They work better on low velocities. However, media manufacturers add a tackifier (glue) to the media to enhance performance. Consequently, when filters using these medias are tested (using ANSI/ASHRAE 52.2) they can have a relatively high MERV. Since the particle capture mechanisms for these types of filters work best at low velocities, they are normally tested at 295 fpm. The media we decided to test in the Permanent Frame Corsi-Rosenthal Box is a MERV 11 (at 295 fpm). Of course, the air velocity in a Corsi-Rosenthal box is well over 500 fpm – even on the lowest fan speed setting.

As it turns out, the higher air flow velocity has a major effect on the filter efficiency of the high loft polyester media. For the three smallest particle sizes (0.3um, 0.5 um and 1 um) the filter efficiency was 10% or less. Even at 2.5 um the filter efficiency was only 29%. If we assume the target particle size for SARS-Cov-2 is 0.5-3um, it is clear that high loft filter media is not suitable for this application.

| Particle Size | Ambient | CR Box w. MERV 11 High Loft Poly Media | Efficiency |

| 0.3 um | 1,048,400 | 1,000,700 | 5% |

| 0.5 um | 172,000 | 159,500 | 7% |

| 1 um | 13,800 | 12,400 | 10% |

| 2.5 um | 7,500 | 5,300 | 29% |

| 5 um | 1,600 | 700 | 56% |

| 10 um | 300 | 100 | 66% |

The noise level from the CR Box with high loft media is fairly consistent with a CR Box using pleat media. The exception is that for some reason the noise is louder on Speed 1. (52 Dba vs. 48/49 Dba)

| Speed | Noise in Decibels (at 3 feet) |

| 1 | 52 Dba |

| 2 | 55 Dba |

| 3 | 59 Dba |

Permanent Frame – Corsi-Rosenthal Box using MERV 13 – 1″ Pleat Media

The holding frames used in this CR Box design are 2″ deep. By using one layer of MERV 13 media pleated to a height of 1″, we would gain enough room to be able to add another filter layer – either to increase filter efficiency or to provide enhanced performance.

Corsi-Rosenthal Boxes have been used extensively in areas exposed to wildfire smoke. The MERV 13 media does an excellent job of removing particles but does not reduce the gasses in that smoke. In order to remove the gasses, one needs to have molecular filtration. A good molecular filter is made from media with activated carbon. The extra room in the holding frames allows us to have both a particle and a carbon filter – thus combining the benefits of both.

To test the concept, we needed to determine if the MERV 13 1″ pleat media could perform at a high level. Here are the results. It definitely performs like MERV 13 filters.

| Particle Size | Ambient | CR Box with MERV13 – 1″ Pleated Media | Efficiency |

| 0.3 um | 563,100 | 336,800 | 40% |

| 0.5 um | 99,400 | 48,900 | 51% |

| 1 um | 8,900 | 3,200 | 64% |

| 2.5 um | 6,900 | 1,200 | 83% |

| 5 um | 1,300 | 200 | 85% |

| 10 um | 700 | 100 | 86% |

| Fan Speed | Noise in Decibels |

| 1 | 48/49 Dba |

| 2 | 55 Dba |

| 3 | 60 Dba |

Permanent Frame – CR Box using MERV 13 – 1″ Pleat Media and Carbon Pad

For the molecular filtration we used 1/4″ carbon impregnated polyester media. Many HEPA air cleaners use a similar media. In areas with high levels of odors and gasses (ie. wildfire smoke) it will need to changed relatively frequently – probably every two weeks. This needs some further research. It could be that thicker carbon media or even granular carbon is required.

It is very easy to replace the carbon media so having it as the outside filter is a plus. However, molecular filtration works better at slower speeds. It could be that reversing the filters would improve the performance of the carbon.

The good news is that there was an increase in efficiency with the combination of MERV 13 media and carbon media. It looks like the second filter layer added to the particle capture rates.

| Particle Size | Ambient | MERV 13 – 1″ Pleat Plus Carbon Pad | Efficiency |

| 0.3 um | 3052000 | 1621300 | 47% |

| 0.5 um | 492900 | 228900 | 54% |

| 1 um | 52700 | 16300 | 69% |

| 2.5 um | 8000 | 1200 | 85% |

| 5 um | 2400 | 300 | 88% |

| 10 um | 1500 | 200 | 87% |

| Fan Speed | Noise in Decibels |

| 1 | 48/49 Dba |

| 2 | 55 Dba |

| 3 | 59 Dba |

There are some disadvantages to using “permanent frames” in Corsi-Rosenthal Boxes.

First, there is higher initial cost. Each Galvanized Holding Frame costs about $25. (But the media is about 50% of the cost of a finished filter.)

Secondly, it is more difficult to assemble the “permanent frame” version. Taping the holding frames together is not difficult. It is basically the same as making a standard CR box. But installing the media in the frames is not easy. It takes time, experience and gloves. Once someone becomes proficient at it, it should go quickly. However, it is “not as easy as “taping a box” to ship.”

Third, since the person changing the filter is touching the media, extra care needs to be taken to ensure the proper equipment and procedures are used. The media needs to changed outside. Gloves and a respirator (N95) need to be worn. The media needs to be disposed of in plastic bags. It can be done safely, but it is not just a matter of cutting the tape from the used filters.

In summary, it looks like the “permanent frame” version of the Corsi-Rosenthal Box has some real potential. Even though the media is not glued to the frame, filter efficiency is maintained. The higher initial cost is offset by lower filter replacement costs. This could be a big advantage where a substantial number of filter sets need to be changed on a regular basis. For example, schools could change the filters on their CR boxes at the same time they change filters in their HVAC systems.

Most importantly, this “permanent frame” design is not the end of the ongoing process of the development of the Corsi-Rosenthal Box. It is a simple idea – that just keeps getting better. It works!