Currently, air filters are tested in the United States according to the procedures described in ANSI/ASHRAE Standard 52.2-2012. This test procedure results in a Minumum Efficiency Reporting Value (MERV) for an air filter. For details of how the test is conducted see other articles on this site. There is a movement to approve the new ISO 16890 testing procedure to replace ASHRAE 52.2 with the goal of having the same test worldwide. This makes sense from a commercial point of view and could help to eliminate confusion in the marketplace. However, there are some serious flaws in the ISO 16890 test procedure that make it unacceptable to a large part of the US market. It is the purpose of this article to explain these flaws and to suggest a possible alternative.

First, it is important to understand the differences in HVAC (Heating, Ventilation and Air Conditioning) between the United States and Europe (the principle source of most ISO standards). The easiest place to start is to look at what we mean when we say “air filter.”

In Europe an “air filter” usually looks something like this:

In the United States the majority of air filters look something like this:

In a conversation I had with the chief executive of one of the large international filter companies I was told the same thing. Pleated filters were not considered to be air filters. They were pre-filters to be used in conjunction with real air filters – like pocket filters. This difference in perception has a major influence on how we need to look at air filter testing.

So why do filter people in Europe have a different conception of an air filter than people in the US? The biggest reason is air conditioning. In Europe filters are used primarily for ventilation. In essence, Europeans in most areas are concerned with the HV (Heating and Ventilation) part of HVAC. Air conditioning is pretty much an American phenomenon. We are the ones that have the higher temperatures. Rome, Italy is roughly the same latitude as New York City. The phenomenal growth in the United States has taken place in the South and Southwest. Without air conditioning these areas were essentially uninhabitable – except for the hardy few. For example, before the invention of air conditioning in 1940 the population of the metro Phoenix area was 65,000. Today the metro Phoenix area is home to more than 4,000,000.

So how do Europeans look at it? As an article in the Washington Post of July 2015 put it – “Europe to America: Your love of air conditioning is stupid.” It is expensive, uses too much energy and oftentimes does not provide for enough fresh air. Americans, on the other hand, consider it a necessity.

Air conditioning needs air flow. Many of the AC systems in the United States today do not have the additional power needed to provide the air flow required to overcome the increased resistance of a high efficiency filter. Also, many systems have not been designed to allow the room necessary for a deeper pocket filter like the one shown above. So without spending billions of dollars for upgrades of HVAC systems, the pleated filter (or some variation thereof) is here to stay.

The cornerstone of the ISO 16890 Test Standard is the use of PM1, PM2.5 and PM10. These are outdoor air measurements signifying the mass of particles below certain thresholds – 1 micrometer, 2.5 micrometers and 10 micrometers. Numerous studies have shown negative health effects from excessive levels of particles in these ranges. Many of the most recent studies have focused on the problems arising from high levels of PM2.5 and PM1 particles. Reducing human exposure to particles in these ranges is an admirable goal.

The proposed ISO 16890 has 4 filter ratings – 1.ISO Coarse <50% E(PM10), 2.ISO PM10 >50% E(PM10), 3.ISO PM2.5 >40% E-min(PM2.5) and >50 E(PM2.5, and 4. ISO (PM1) >40%E-min (PM1) and >50% E(PM1). Particle sizes of 0.3um to 10um are used in the test. All filters are totally discharged using IPA vapor.

The ranges in ISO 16890 are supposed to help the user determine what filter to use. In supporting documentation for ISO 16890 it states that: “The outdoor air quality classes (ODA1 to ODA3) for the air to be filtered and the required indoor air quality, which is divided into the 4 classes should be used as the basis for selecting the filter or filter combinations.” For filters used strictly for ventilation bringing in outside air this is sensible. For American HVAC systems – it is not useful at all. Here’s why.

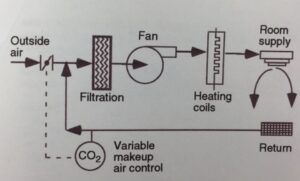

In the US we use recirculating HVAC systems almost exclusively. In commercial buildings we allow for up to 30% outside air. In residential HVAC systems outside air is often supplied only by leakage in the building envelope. A commercial system looks something like this:

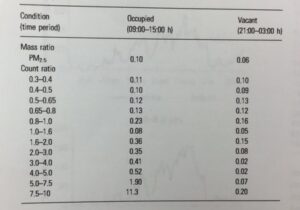

A very interesting study entitled “Particle Size Distribution and Composition in a Mechanically Ventilated School Building During Air Pollution Episodes” by J.L. Parker, et al published in the Indoor Air Journal July 2008 sheds some light on what happens in a building using a recirculating HVAC system in periods of high PM2.5 and PM10. The building used a Variable Air Volume system with MERV 8 filtration (probably a PM10 in ISO 16890).

The chart below gives the ratio of concentration inside the school library to the outdoor particle concentration averaged over the indicated times for the five most polluted school days during the study period.

Using the premise of filter selection in ISO 16890 one would think that the particle counts in the small particle ranges would have been very high. In fact, they were quite low and went from 0.10 to 0.23 of outside levels. It appears that the building envelope and the mechanical ventilation system using a MERV 8 filter did a pretty good job of protecting teachers and students from outdoor air pollution.

To me the most revealing information provided by this study is what happened with the larger particles. They were much higher in the “occupied” readings than the “vacant” particle readings and culminated in the 7.5um to 10um particles being 11.3 times the particles outside and over 50 times the particles in this range when the building was unoccupied. Particle levels in indoor air are dependent on a number of factors including activity in the space, filtration, air exchange rates, type of HVAC system, differential pressure, ventilation and other forces such as gravity (also a very effective filter for larger particles). The point is – ISO 16890 proposes to make it simple. Select a filter for your desired level of indoor air quality and it’s done. Not true. Never has been – never will be.

Another important component of ISO 16890 is that it requires all filters to be “discharged” before testing. The purpose of this is that manufacturers have been able to produce media that is “charged” to enhance particle efficiency and reduce resistance. As dirt builds up on the “charged” media, the attraction effect is reduced. Depending on the size of the charged fiber and the level of the charge, this effect can occur relatively quickly. The result is that a high efficiency filters (MERV 13 and above) out of the box might not be as high efficiency in 60-90 days in use. I can see and understand this point.

But ISO 16890 requires that all filters be “discharged” before testing. This is where there is a real problem with the standard and a major reason why it should not be accepted as a US Standard. My reasoning goes back to the original premise of this article – HVAC systems are different in the US and we need to make sure we recognize this difference.

Pleated filters using “charged” media have some distinct advantages over pleated filters using mechanical only media. The two most important are: 1. reduced resistance and 2. higher efficiency on small particles (less than 1um). In the ASHRAE 52.2 test particles in the 0.3um to 1um range are classified as E1. Pleated filters using charged (electret) media typically have an E1 of 25% to 30%. Mechanical filters with the same MERV have an E1 of 5% to 7%. In other words, the electret pleated filters are 4 to 6 times more efficient on E1 particles than mechanical pleated filters.

Now 25% to 30% efficiency on E1 particles does not seem very high. However, remember that the tests only measure single pass efficiency. Our HVAC systems in North America are recirculating systems which means that the 25% to 30% removal occurs with each air exchange. Over time this difference is significant since the 0.3um to 1um particles are the ones that stay in the air for an extended period of time (unless removed).

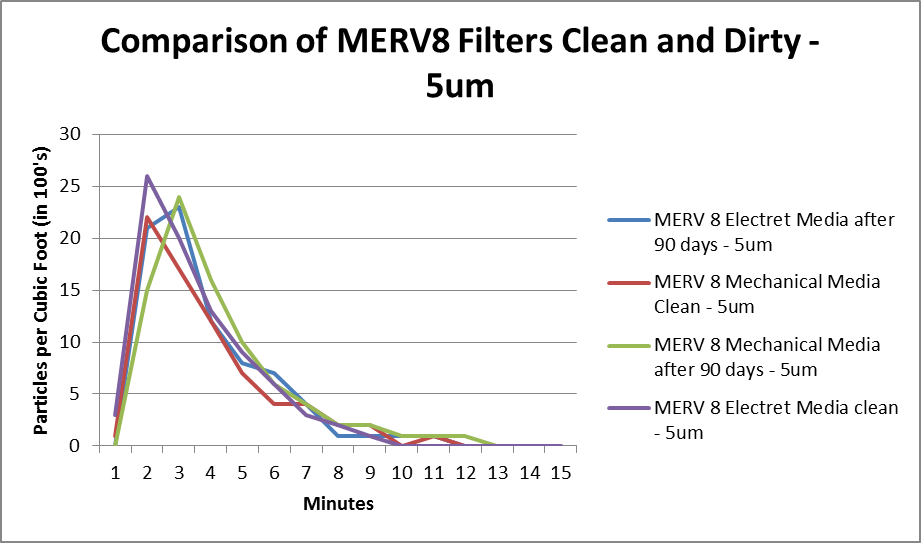

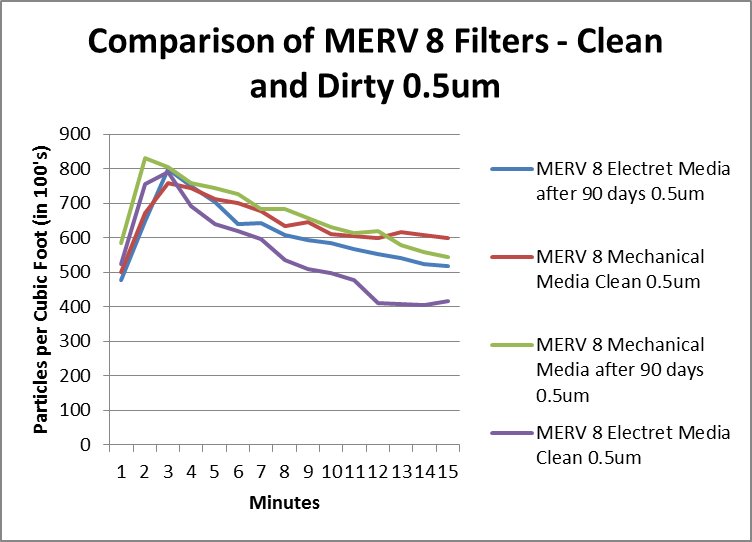

To illustrate this point we conducted some tests comparing the efficiency of electret pleated filters and mechanical pleated filters in a room environment using a recirculating air cleaning device. The room was 120 square feet. The device was set to provide 20 ACH. We created particles in the room at the start of each test. Four filters were tested – 1. Pleated Electret New, 2. Pleated Electret that had been used in a commercial building for 90 days, 3. Pleated Mechanical New, and 4. Pleated Mechanical that had been used in a building for 90 days. The results were the following:

Figure 8

At 5um all four filters performed at about the same level. There was no appreciable decrease in electret filter performance with use. The fact is 5um particles are relatively easy for pleated filters to remove from indoor air – if they reach the filters.

The results at 0.5um are more interesting:

Figure 5

The new electret pleated filters are about twice as efficient at removing 0.5um particles as the mechanical pleated filters. While the electret pleated filters did decrease in efficiency after 90 days of use, they were still more efficient at removing 0.5um particles than either the new mechanical pleated filter or the mechanical filter that had been used for 90 days.

So when ISO 16890 includes a mandatory step of discharging all filters before testing, it neutralizes all benefits of the electret pleated filter. This does not represent “real life” and is done to the detriment of filter users. As we look at the future of air filter testing this needs to be taken into consideration. Possibly a two-tier testing system with MERV 13 and above requiring a conditioning step and MERV 12 and below with no conditioning step.

ASHRAE 52.2 may not be perfect, but it is better than ISO 16890 for the North American market. Therefore, we need to resist a transition that will be very costly and give us no benefits for filter manufacturers, filter marketers and filter users.

(NOTE: I have asked several indoor air scientists to review this paper and their consensus is that outdoor air entering through open windows and doors is understated. In most areas of the world, open windows and doors are the primary method of ventilation for the vast majority of buildings. At least for six months of the year large quantities of potentially polluted outdoor air enters the indoor spaces. This air is unfiltered and overwhelms the ability of any system to effectively remove particles. The result is the use of ISO 16890 testing to address high levels of PM1, PM2.5 and PM10 is meaningless for much of the year in the vast majority of buildings around the world.)

As we move forward an effort needs to be made to align filter testing with indoor air quality requirements. Single pass tests have limited usefulness in this regard. Some in the filter industry have proposed testing using a recirculating test apparatus. This shows real promise and would be more in line with the HVAC systems used in the United States. As such it would represent substantial improvement over current testing methods and should be encouraged and supported.