Different MERV 8 Filters do not perform in the same way on all particle size ranges. Pleated filters have far higher efficiency on medium sized and small sized particles than polyester pads or ring panels.

The ASHRAE 52.2 test method is designed to measure the fractional efficiency of a filter by particle size. One would think that two filters with the same MERV number would perform in about the same way. This is clearly not the case and performance varies widely with different types of filters.

The best example of this discrepancy takes place with MERV 8 filters. The three major types of MERV 8 filters on the market today are pleated filters, ring panels and tackified polyester pads. In the ASHRAE 52.2 test, average efficiency is calculated on the basis of three particle size ranges – E1= 0.3 to 1 micrometer, E2= 1-3 micrometers and E3= 3-10 micrometers. In order to be classified as a MERV 8 filter the E3 needs to be over 70%. In other words when the filter is exposed to particles in the test duct the filter needs to be able to remove this percentage of 3 to 10 micrometer sized particles. So all three types of filters would exceed this 70% figure. But here is the interesting thing – a typical MERV8 tackified polyester filter has an E1 of 4%, a typical 3-ply MERV8 ring panel has an E1 of 4.7% and a typical MERV8 pleated filter has an E1 of 27.7%. The MERV8 pleated filter is six to seven times more efficient on fine particles!

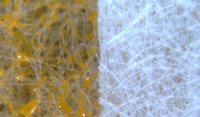

Why? The answer lies in the composition of the filter. The picture above shows MERV8 filter pleated filter media side by side with MERV 8 tackified polyester media. In the case of the pleated media the fibers are relatively small and densely formed. In the case of the polyester media the fibers are relatively far apart and a tackifier (or glue) has been added to enhance performance. The pleated media is able to utilize all of the mechanisms of filtration including straining, impaction, interception and diffusion. On the other hand, the tackified polyester media and ring panels are only able to utilize one mechanism – impaction (or impingement). To make up for this, a tackifier is added to capture the larger particles. Unfortunately, as you can see in the picture, the gap between fibers is still substantial. The result is that smaller particles simply pass through the filter and will continue to do so until the filter is sufficiently dirty to provide more resistance and particle capture ability.

Another significant difference between MERV8 pleated filters and MERV8 tackified polyester and ring panel filters is that the pleated filters have lower resistance and cause less pressure drop. Even though the media is denser on a pleated filter there is more surface area. This means that the air flowing into the filter is distributed over a wider area. The flat surface of polyester pads and ring panels are limited to their outside dimensions in terms of surface area. Test results again show this difference. A typical tackified polyester pad has a pressure drop of .25″wg at 300 fpm and .46″wg at 500 fpm. A typical 3-ply ring panel has a pressure drop of .19″ wg at 300 fpm and a .46″ wg at 500 fpm. While a typical 2″ MERV8 pleated filter has a pressure drop of .14″ wg at 300 fpm and a .27″ wg at 500 fpm. This increase in static pressure attributable to the tackified polyester pads and ring panels can result in higher energy costs due to longer run times to achieve desired interior temperatures and to HVAC motors having to work harder to move the same amount of air. So not only are tackified polyester pads and ring panels very ineffective on particles of one micrometer or less, they also add to operation costs because of their much higher resistance.