By Jim Rosenthal

Several months ago I wrote two articles for this site on the “Box Fan and MERV 13 Filter” air cleaner. They have been viewed over 30,000 times and many people have built these air cleaners following the simple directions in the articles. They are easy to construct, inexpensive and effective. In short, they work!

Many were built for additional protection from exposure to airborne Covid-19. Based on the number and timing of the views of the articles, many more people have used them for reducing the effects of wildfire smoke.

A few weeks ago I was measuring the airflow of a “Corsi Box” and noticed that it was significantly reduced in the “corners” of the box fan. In fact, in the areas closest to the corners, the air was actually going in the opposite direction. It was moving toward the fan.

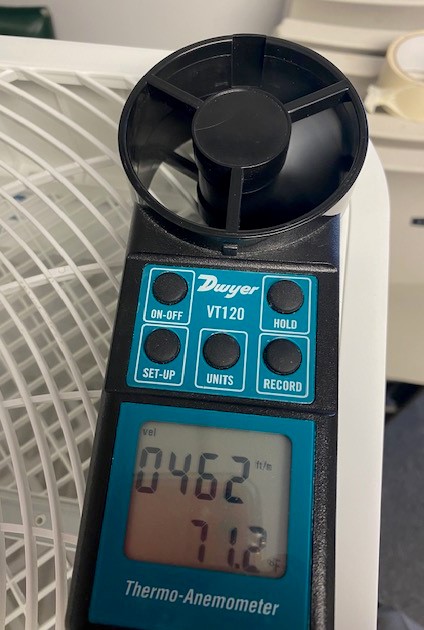

I didn’t think it was a big deal until I received an email from Sam Bullard of Charlotte, North Carolina. Sam is not an HVAC practitioner. He is a homeowner who tries to “figure things out.” He was able to solve the HVAC system sizing and ducting problems in his house so that a contractor could do the work properly. In the process, he read Manual J, bought the instruments and did the measurements necessary to prove his points. One of those instruments was an anemometer. This device is like a small windmill that tells airflow direction and velocity. He detected the same reverse direction air flow in the corners of the box fan that I had seen.

So, what is going on here? How could the airflow at the corners be going in the opposite direction? Simple. The positive airflow pressure from the fan creates negative pressure at the perimeter of the fan. Since the round fan is in a square box, there are gaps at the corners where this negative pressure results in the counter-flow. These pictures will provide a better explanation of the concept.

The “net” airflow – plus from the fan minus negative on the corners – is significantly positive. However, this is not the best situation and, at least for the “Corsi Box,” it can result in some air not going through the filters.

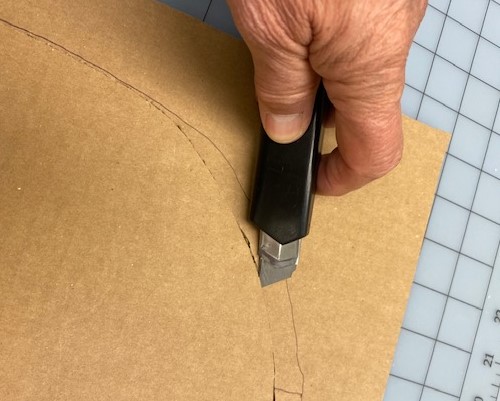

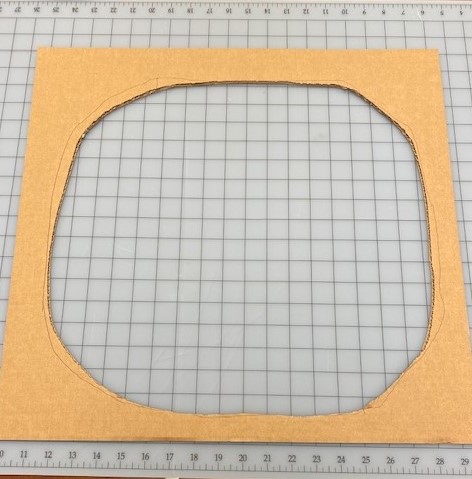

How do we solve this? Believe it or not, we are not the first ones to encounter the problems of putting a round fan in a square box. The automotive industry has dealt with it for many years. Fans are used on cars and trucks to cool the radiator. In order to direct the air flow from the fan, they use what is known as a “fan shroud.” This closes the gaps at the corners and stops the turbulence that reduces the efficiency of the fan. Let’s use the same concept of a “fan shroud” on the “Box Fan and MERV 13 filter

There was no increase in energy usage for the fan motor on the “Corsi Box” used for this test. There was no increase in motor temperature.

The effect of the “counter-flow” of air varies by fan model. On some models a larger “fan shroud” is needed. It is not necessary to use a “fan shroud” like the one shown above. On one of my fans, I just taped the front of the fan on the corners and it seemed to work just fine.

Another option is to tape the filter on the front of the fan. In this configuration there was no “counter-flow” effect that was detectable. The disadvantage of the filter in front is that it reduces air flow through the filter. For example, for a box fan I just tested, the airflow with the filter on the front of the fan was 260 fpm. On the other hand the airflow on a fan with the shroud, at the same fan speed and with the filter on the air intake side was 680 fpm. Total filtered air leaving the device with the filter on the air leaving side was 720 cfm. Total filtered air leaving the device with the fan shroud and the filter on the air entering side was 1,065 cfm.

Is the “fan shroud” tweak of the Box Fan and MERV 13 Filter air cleaner absolutely necessary? No, but it does improve the performance. It just takes a few minutes to do. I am adding it as an additional step in both of the articles on building this air cleaner. It works!